Max Robson, Head of Recolight’s LCA Service, discusses how an LCA can help UK lighting manufacturers gain a green edge.

Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs) are increasingly important for lighting manufacturers. The task of compiling environmental data for extensive ranges of luminaires can be daunting. However, with growing pressure from specifiers and end-users to provide credible environmental metrics, companies that move early will gain a competitive advantage.

The driving force behind environmental metrics

An increasing number of specifiers and end-users are now requiring credible environmental metrics as part of their lighting procurement and specification. Those companies that move early will gain a competitive advantage.

When considering the environmental impact of a luminaire, we often talk about light source efficiency. To this end, the uptake of highly efficient LED lamps has been a significant step in the right direction. However, a holistic appreciation of a product is needed to understand its true environmental impact. This can be achieved via a Life Cycle Assessment (LCA) and Environmental Product Declarations (EPDs).

By generating LCAs and EPDs, lighting manufacturers will better understand the impact of their products and satisfy increasing specifier and client requirements for achieving green certifications like BREEAM, LEED, Net Zero, and more. LCA results can also serve as guidance for innovation towards more sustainable and circular lighting solutions.

The LCA process

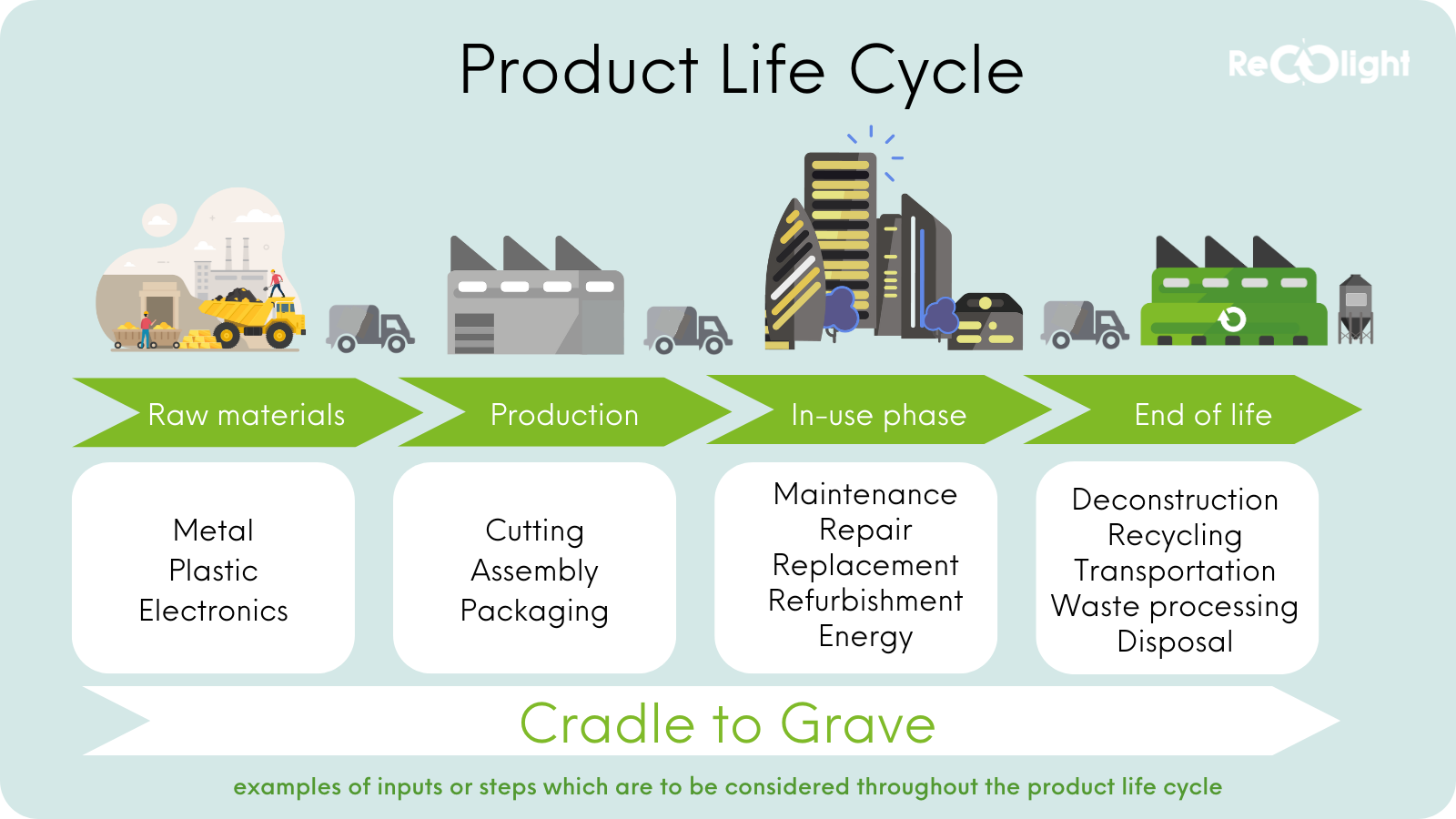

Life Cycle Assessment is a methodology for assessing environmental impacts associated with all stages of the life cycle of a commercial product, process, or service. Environmental impacts are assessed from raw material extraction and processing (cradle), through the product’s manufacture, distribution, and use, to the recycling or final disposal (grave).

The LCA follows a systematic approach that involves four main components:

- Defining the goal and scope of the analysis

Establishes the purpose, system boundaries, functional unit, and key assumptions of the study. - Inventory analysis

This is the data collection step during which all inputs and outputs of a process are considered. These often include materials, energy, water, and auxiliaries needed throughout the whole life cycle. - Life Cycle Impact Assessment (LCIA)

Life Cycle Impact Assessment (LCIA) involves evaluating the potential environmental impacts of a product system throughout its life cycle. For example, global warming potential, land use, water use, and eutrophication. - Results reporting

The final stage of the LCA process is where the findings are interpreted. Here, the analysis is checked for reliability to allow for meaningful and accurate conclusions.

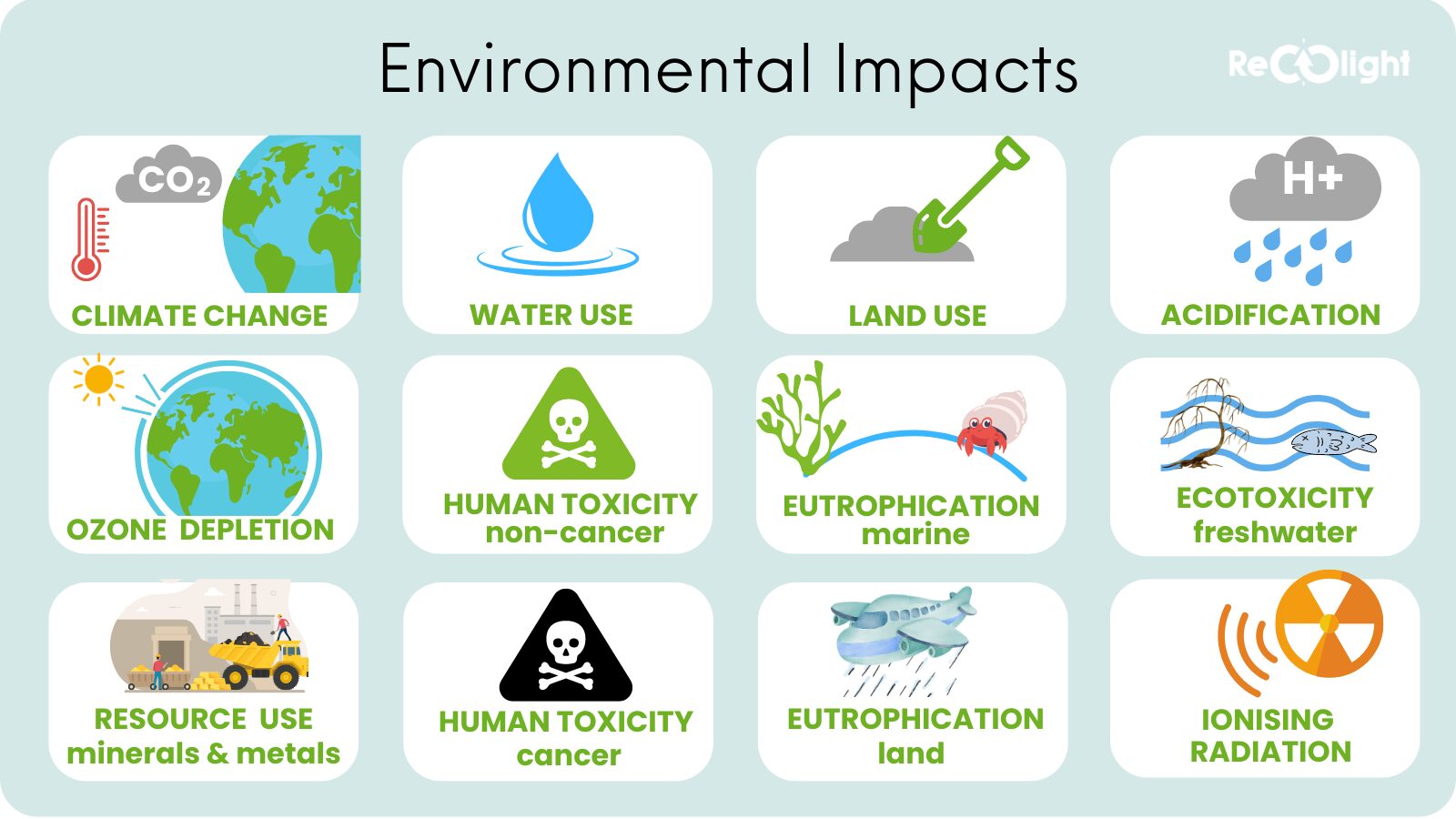

Environmental impacts

The environmental impact of a product or service cannot only be captured by its global warming potential (CO₂ equivalents) as there are many other environmental impact categories to consider.

Using an LCA, a manufacturer can measure a product’s impact across all categories. An LCA also allows a company to model the implications of a potential change to a product. For example, this could be the use of an alternative component material or manufacturing process. These can often be associated with environmental trade-offs (e.g., a design measure that decreases climate impacts but increases toxicity impacts). This way, product designers can still choose to prioritise climate impact while being aware of the impact on other categories.

Each category is calculated based on all the emissions which contribute to that impact. For example, the impact category ‘Global Warming Potential’ (GWP) is expressed in kilograms of CO₂ equivalents (kg CO₂-eq). However, other greenhouse gases have global warming potentials too. These are each converted into the equivalent amount of CO₂ which has the same potential impact. The same calculations are conducted for each impact category.

Given that each impact category has different units, they cannot be combined into one ‘total’ impact value. Therefore, LCA results are typically reported as tables of data, although GWP always takes the limelight.

Product life cycle

To truly understand the impacts of manufacturing a product, the entire life cycle should ideally be considered.

Environmental Product Declaration (EPD)

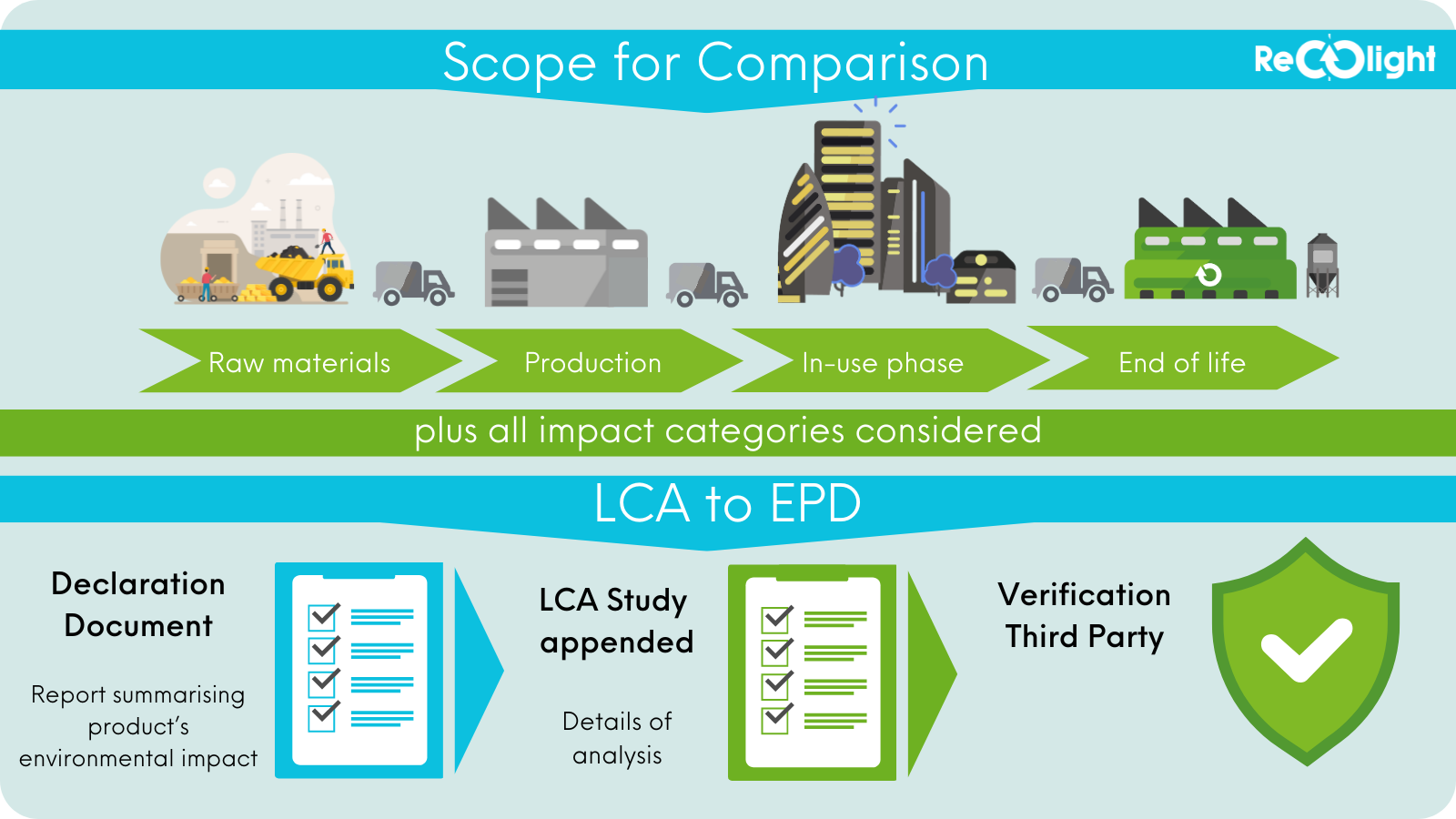

An Environmental Product Declaration (EPD) is a transparent and verified environmental declaration that contains quantitative information about a product’s lifecycle. The information declared within an EPD is calculated using the LCA methodology. Therefore, an EPD report requires an LCA study.

Here’s a quick refresher to help you understand the different terms:

LCA

- Assessment of the total environmental impact of a product or service.

- Flexible scope of study – useful when the whole life cycle doesn’t need to be considered.

- Results aren’t in the public domain.

EPD

- Transparent summary of a product’s environmental impact.

- Must follow Product Category Rules to be valid.

- Third-party verified.

- Final report is published in the public domain.

An EPD is defined by the International Organization for Standardization (ISO) 14025 as a Type III declaration that “quantifies environmental information on the life cycle of a product to enable comparisons between products fulfilling the same function.”

The EPD consists of two key documents:

The underlying Life Cycle Assessment report

This is a systematic and comprehensive summary of the LCA project to support the third-party verifying the EPD. It is not part of public communication.

Public EPD document

Documenting the LCA results and other EPD content.

The process of getting a complete, verified EPD is multistep. By far the most time consuming is the LCA study, which requires data collection and all the calculations. The results are then used to fill in an EPD document – the ‘declaration document’. This must then be submitted to a third-party verifier, before It can be published.

The LCA Service for lighting manufacturers

If the process of creating an LCA seems daunting, help is at hand. As of September 2024, Recolight is offering a new LCA service to UK lighting manufacturers. This service provides education and support throughout the LCA/EPD journey. Recolight has partnered with the industry-leading One Click LCA platform to deliver expertise, guidance, and world-leading LCA and EPD technology to the lighting industry.

The Recolight LCA service includes:

- Workshops that cover the need-to-knows before starting the LCA and EPD journey.

- Access to the One Click LCA software and support for onboarding and ongoing analysis of luminaire products and catalogues.

Recolight and One Click LCA’s deep understanding of the lighting industry will provide support and guidance, helping companies cut through the complexity of environmental metrics.