Solon Mardapittas, CEO at Powerstar, looks at some misconceptions around voltage optimisation and the real benefits of the technology.

Voltage optimisation can significantly improve energy efficiency – lowering energy bills and reducing carbon emissions. But overpromising on blanket cost savings and project payback time can create confusion for customers.

As a transformer-based technology, voltage optimisation helps ensure that the energy supply from the grid matches what the on-site equipment demands. This is especially important as what is actually coming in can hugely vary, by as much as 10%.

Under UK regulations, the mains supply voltage should be within +10% and -6% of 230V, which means that the actual permitted voltage range could be anywhere between 216V and 253V. In many cases, it’ll be on the higher side, as the National Grid generally supplies at higher than 230V to ensure that it meets its statutory obligations.

In fact, when looking at what is typical for National Grid, you will soon find that the average grid voltage supply is around 242V. This is interesting because most UK electrical equipment has been designed to operate at 220V – meaning the higher than necessary operating voltage leads to both wasted energy and the potential for damage to equipment through unnecessary wear and tear.

This problem is one that could potentially cost companies significant amounts of money both in terms of energy use and higher maintenance costs, as well as inflated carbon emissions associated with energy usage (Scope 2 emissions). The potential risk to equipment could also lead to more frequent maintenance intervals, which could have a reputational or financial cost in itself for the period of downtime.

That’s why voltage optimisation technology is available, as it eliminates overvoltage and returns the unnecessary voltage back to the grid, while ensuring that the power going to the equipment is consistent and clean. However, while this might suggest that voltage optimisation is a good investment for just about any business, it’s not quite the full story.

Don’t take a one-size-fits-all approach

To get the most out of voltage optimisation, it’s important to look at the nature of a company’s operations. It’s certainly true to suggest that different types of companies will have a different experience with voltage optimisation – some having a shorter payback period and enjoying more pronounced benefits than others.

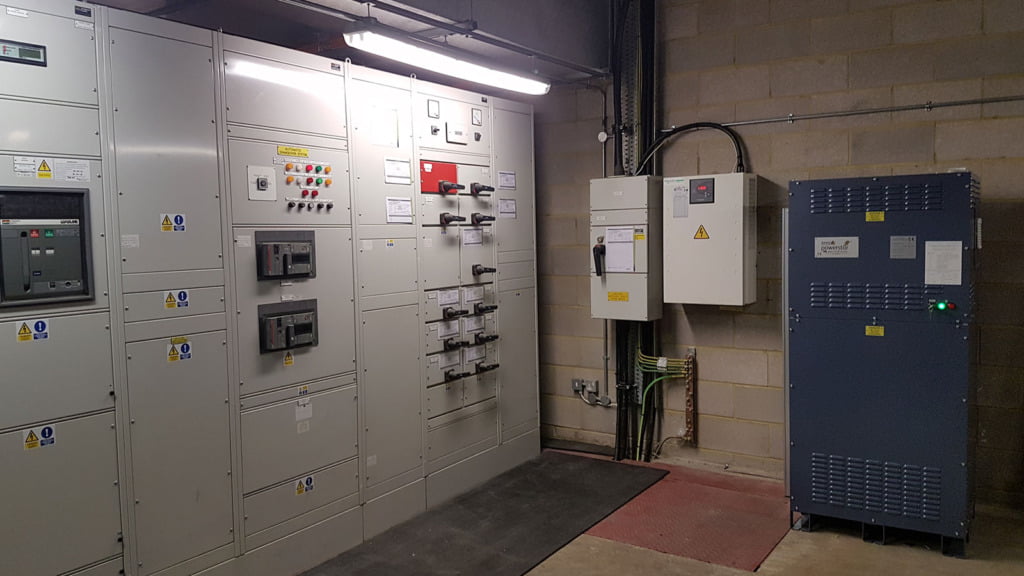

As an example, one of the largest family-owned food manufacturers and retailers in North East England, M I Dickson, recently invested in voltage optimisation technology, but it did so with full knowledge of how it would impact its business. To achieve this, the company had an initial inspection to determine the best option to meet their stated aim of improved energy efficiency and carbon emission reductions.

During the site inspection, the company was found to have unstable and higher than necessary voltage supply, which meant inflated energy costs and unnecessary carbon emissions. It was at this point the business was told that voltage optimisation could likely help – rather than predetermining the outcome.

However, rather than setting one voltage level, as many VO solutions providers offer, the option chosen to specifically suit the business’ need would dynamically regulate the incoming voltage level, offering online remote monitoring capabilities, and giving M I Dickson access to performance data in real-time.

The result? Based on the same 35-day period, across two years, site consumption decreased by more than 8,000 KWh since the installation of voltage optimisation, despite production volume being increased by around 10%. And, in the context of production volume, savings per tonne of product equates to 52.8 kWh, a consumption saving of 13% per tonne.

Investment considerations

When looking to invest, even in the midst of an energy crisis, any organisation considering voltage optimisation should look for a partner who will review their energy data as a first step to establish benefit projections.

This is becoming especially important now, as while voltage optimisation could previously offer huge savings, many technologies are becoming increasingly energy efficient, which means the actual savings could be lower than they were several years ago.

Similarly, actual financial savings will be linked to the voltage profile of a site, meaning that the highest savings apply to sites where overvoltage is a consistent issue. It is impossible to offer an accurate percentage saving without proper site analysis.

While some providers may indicate such blanket savings, these can’t be predicted without actual data. Some operating in the voltage optimisation market have offered guaranteed savings up to 20% on energy bills, with payback periods of less than 12 months. But different sectors, different patterns of operation, and different geographical locations are all factors that inform actual savings.

Both cost-efficiency and energy-efficiency come from a holistic view of site infrastructure and operation, not from the implementation of voltage optimisation technology, per se. Put simply, to deliver savings there must be voltage-related losses somewhere across the existing electrical infrastructure.

Voltage optimisation – best practices

So, when looking to establish whether voltage optimisation is a good fit, it’s imperative to understand the company you’re working with. When working towards better energy efficiency and helping a business reduce their carbon emissions, an initial site inspection and a thorough review of their operations is critical.

Sure, the headline benefits of voltage optimisation are compelling – potential savings on energy bills and lower CO2 emissions – but cost benefits can only be accurately determined on a case-by-case basis.

Of course, that’s not to say there won’t be any cost benefits on the majority of projects, as most sites are likely to see an immediate cost benefit given the general overvoltage from grid supply. However, it’s important to get a good idea of exactly how much savings could be had before making such an important investment decision.

Plus, let’s not forget it’s not just about energy savings. There are additional significant benefits related to improved performance: reduced maintenance costs; the better usage of expensive and business-critical assets; and reduced wear and tear on expensive electrical and electronic equipment, to extend its lifespan. All of these aspects can only really be determined through a full survey.