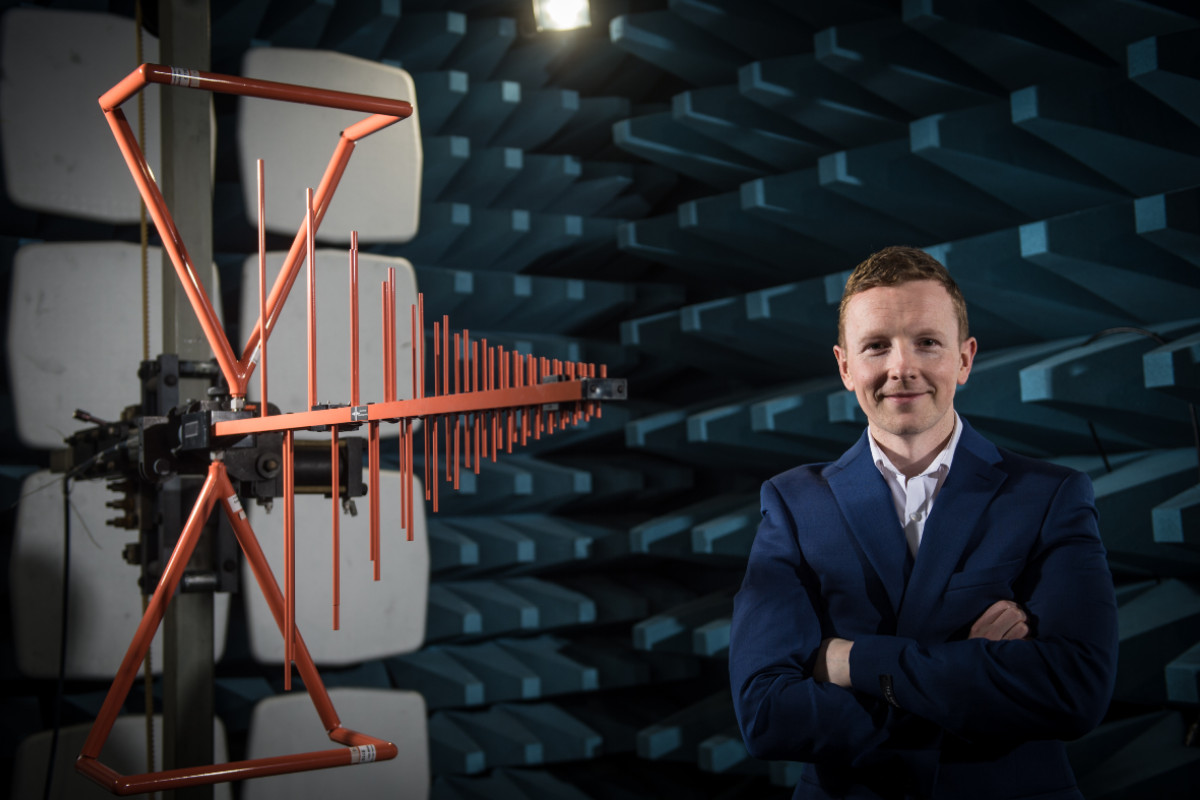

By following a clear six-step process, manufacturers can swap compliance headaches for a fast, trusted route into global markets, says Leigh Picton, Laboratory Manager at Kiwa.

Step one: The initial consultation

The safety certification process begins with an initial consultation, where manufacturers submit a Request for Quotation (RFQ) to a certification provider. This step defines the exact scope of the testing and clearly specifies the countries or regions where the product will be launched.

From there, the certification provider develops a customised testing roadmap. It outlines key milestones, resources required, and estimated costs. Engaging with a trusted partner early allows for better resource allocation, a clearer understanding of challenges, and a defined route towards certification.

Step two: Product details and documentation

Once the scope and costs are settled, manufacturers submit a test sample of their product along with essential documentation, including:

- Manufacturer information and manufacturing site addresses

- A detailed product description

- Documentation for each component used in the product.

At this stage, every component, with a particular focus on safety-critical parts, must meet local and international regulations. Obtaining certifications for these components at the earliest opportunity is crucial to avoid delays further down the line.

Step three: Testing and assessment

Once the product and documentation are received, the certification provider begins testing the product against International Electrotechnical Commission (IEC) standards along with specific requirements for target markets.

Testing ensures compliance with both global standards and local regulations. For efficiency, manufacturers should look to work with a provider equipped to conduct all testing in-house. Dedicated facilities and experienced engineers can significantly reduce turnaround times while maintaining the highest standards of accuracy.

If any issues arise, manufacturers are informed promptly, enabling swift resolutions. Transparency and ongoing collaboration between manufacturers and certification bodies are critical during this phase. A well-communicated process ensures clarity and keeps the project on track.

Step four: Feedback and resolution

Following testing, the certification provider delivers a ‘findings letter’ identifying any outstanding issues that require manufacturer attention. Promptly addressing these recommendations minimises delays in the overall certification process and ensures compliance.

Whether adjustments involve modifying components or refining documentation, collaboration during this stage ensures the product meets all safety requirements before progressing further.

Step five: Issuing the CB Test Certificate and Report

After all compliance issues are successfully addressed, the certification body issues a CB Test Certificate and Report. These documents are crucial in securing access into global target markets.

CB certification allows manufacturers to bypass redundant testing by demonstrating compliance with international standards, saving time and cost. However, regional variations might require additional certifications. For example, products entering the USA often need an NRTL (Nationally Recognised Testing Laboratory) mark.

Step six: Product launch

With certifications awarded, manufacturers are ready to launch their products confidently. They can rest assured that their offering is safe, compliant with global standards, and market ready.

It is important to remember that opting not to obtain correct certification presents many critical risks, as it exposes both consumers and manufacturers to potential harm, reputational damage, and costly legal ramifications. On the other hand, collaborating with trusted certification providers safeguards all parties and facilitates smoother product launches.

Navigating electrical safety certification may seem daunting, but a clear and structured process makes it both streamlined and achievable. By following the six-step pathway and partnering with an expert certification provider, manufacturers can ensure their products are compliant, safe, and globally trusted.