Power transformers serve as the backbone of electrical infrastructure, enabling the efficient transmission and distribution of electricity. Given their key role, utilities and transformer asset managers must adopt strategic maintenance, repair, and replacement methodologies to ensure uninterrupted performance and longevity.

One of the most effective methodologies for condition assessment and lifecycle optimisation is the Transformer Health Index (THI). This index aggregates multiple diagnostic parameters to deliver a comprehensive evaluation of a transformer’s reliability, thereby informing predictive maintenance strategies and risk mitigation measures.

Transformer Health Index: A strategic asset management framework

The Transformer Health Index (THI) is a holistic, quantitative assessment tool that consolidates multiple diagnostic parameters to generate a single numerical representation of a transformer’s condition. By integrating THI into asset management frameworks, utilities can optimise transformer maintenance schedules, reduce operational costs, and minimize unplanned outages. The key parameters contributing to THI calculation include:

- Dissolved Gas Analysis (DGA) – A critical diagnostic tool for detecting incipient faults.

- Oil Quality Assessment – Evaluates degradation of insulating oil and contamination levels.

- Load History and Operational Conditions – Analyses the impact of thermal and electrical stresses.

- Physical and Visual Inspections – Identifies mechanical deformities and insulation conditions.

- Temperature and Electrical Performance Metrics – Monitors winding temperatures, dielectric strength, and load flow parameters.

Through the systematic application of THI, utilities can extend the operational lifespan of transformers, prevent catastrophic failures, and implement cost-effective maintenance interventions.

The role of Dissolved Gas Analysis (DGA) in THI

DGA is one of the most crucial and widely utilised components of THI. It provides early detection of developing faults by analysing the gases dissolved in transformer oil, which serve as indicators of various failure modes. The primary gases and their diagnostic significance include:

- Hydrogen (H₂) – A marker for partial discharges and low-energy arcing.

- Methane (CH₄) – Signifies overheating of oil due to moderate thermal faults.

- Ethane (C₂H₆) and Ethylene (C₂H₄) – Indicate more severe thermal faults affecting insulation and oil.

- Acetylene (C₂H₂) – A primary indicator of high-energy arcing faults, often signaling imminent failure.

- Carbon Monoxide (CO) and Carbon Dioxide (CO₂) – Associated with paper insulation degradation, crucial for assessing insulation health.

By incorporating DGA into predictive maintenance regimes, asset managers can proactively address emerging faults before they evolve into critical failures, thereby enhancing the reliability of the power network.

The critical importance of acetylene (C₂H₂) in DGA

Among the gases analysed in DGA, acetylene stands out as the most diagnostically significant. Acetylene is an unmistakable marker of high-energy electrical arcing, which can rapidly lead to insulation breakdown and catastrophic transformer failure. According to industry benchmarks (OFGEM Common Network Asset Indices Methodology (CNAIM)), acetylene concentrations exceeding 5 ppm necessitate immediate investigation, while levels surpassing 20 ppm indicate critical fault conditions demanding urgent intervention.

Accurate quantification of acetylene concentrations enhances fault diagnosis precision, allowing asset managers to implement timely corrective actions and avert costly transformer failures. Moreover, integrating acetylene trend analysis with other diagnostic metrics strengthens the predictive capabilities of THI, offering a more robust approach to transformer health assessment.

Data-driven insights and graphical analysis

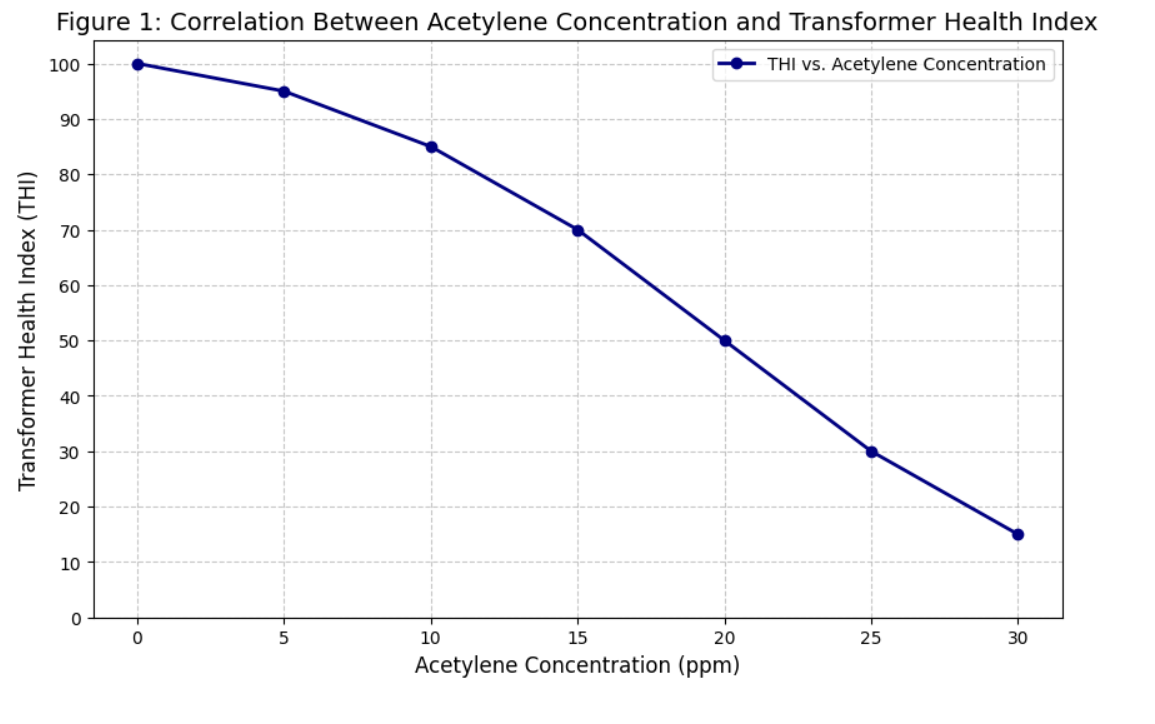

Empirical studies reveal a strong correlation between escalating acetylene concentrations and declining THI scores. Figure 1 illustrates a pronounced decrease in THI values when acetylene levels exceed 20 ppm, underscoring the necessity for timely interventions. Historical trend analysis of DGA datasets further enables predictive modeling, allowing utilities to forecast potential failures and implement condition-based maintenance strategies.

Additionally, advanced machine learning algorithms and artificial intelligence frameworks are increasingly being integrated with THI to enhance diagnostic accuracy. These methodologies facilitate pattern recognition within large-scale DGA datasets, enabling early identification of emerging failure trends and optimization of maintenance schedules.

The future of the Transformer Health Index and AI-driven maintenance

The integration of AI and big data analytics is revolutionising transformer condition assessment. AI-powered predictive maintenance models leverage vast datasets, including historical DGA readings, real-time monitoring inputs, and operational parameters, to improve forecasting accuracy and maintenance planning. Key advancements include:

- Machine learning-based fault prediction – AI models detect subtle fault signatures and predict potential transformer failures with high accuracy.

- Real-time monitoring and adaptive maintenance – IoT sensors provide continuous health tracking, enabling dynamic maintenance adjustments.

- Automated decision support systems – AI-driven insights guide maintenance teams in prioritising interventions based on real-time risk assessments.

These developments not only enhance THI’s effectiveness but also contribute to a more resilient and cost-efficient electrical grid.

Conclusion

The Transformer Health Index is an indispensable asset management tool that enables power utilities to systematically evaluate transformer reliability and operational integrity. Within the THI framework, Dissolved Gas Analysis (DGA) is the most critical factor in Transformer Health Index assessment, providing early fault detection and preventive maintenance capabilities. Within DGA, acetylene is the most valuable gas for diagnosing severe internal electrical faults, particularly arcing, which is a major contributor to catastrophic transformer failures. Accurate acetylene measurement ensures precise fault identification and timely maintenance interventions, enhancing transformer reliability and operational efficiency.

The integration of AI-driven analytics with DGA and THI further revolutionises transformer maintenance strategies. Predictive maintenance powered by machine learning enhances fault detection, optimising maintenance scheduling and reducing operational costs. As the power industry continues its transition toward digitalisation, leveraging data-driven insights from DGA and THI will be paramount in ensuring a stable, efficient, and resilient power infrastructure.

Industry solutions

In addition to the methodologies discussed, tools such as the Megger Insulogix G2 play a pivotal role in transformer health assessment. This advanced instrument is capable of monitoring key gases like hydrogen and acetylene, providing precise data that contribute directly to the Transformer Health Index evaluation. Moreover, Megger offers a versatile range of products for transformer testing that support various maintenance strategies – including time-based maintenance, condition-based maintenance, and predictive maintenance – thereby enabling utilities to plan and execute effective maintenance programs.