A small but essential piece of equipment — the humble circuit breaker — has long had the power to make a big impact across the electrification industry and to energy management in general, explains Sami Raitakoski, Global Head of ABB’s Control & Protection Products.

Most of us take for granted that a flick of a switch or press of a button turns on the lights, starts up a computer, or engages the EV charger, without ever thinking about where this electricity comes from, or how it is delivered.

The circuit breaker plays a critical role in energy distribution networks globally — mainly used in utilities, power generation and renewable applications, or substations in cities — because it protects electrical systems from damage by interrupting and safely re-establishing a disrupted current flow.

By way of example, medium voltage circuit breakers are installed in data centers around the world to ensure the highest data availability — and in a typical facility hosting 130,000 servers, a minimum of five circuit breakers protect the network.

If a power interruption occurs, a circuit breaker isolates the section of the network at risk within milliseconds — which is 10 times faster than the blink of an eye — to safeguard the energy flow. When this happens, the breaker is exposed to intense heat ranging from 5,000 degrees to 6,000 degrees Celsius, temperatures capable of melting rocks.

So, next time you settle down to watch your favorite TV show without any interruption, spare a thought for medium voltage circuit breakers, which are providing optimal power flow.

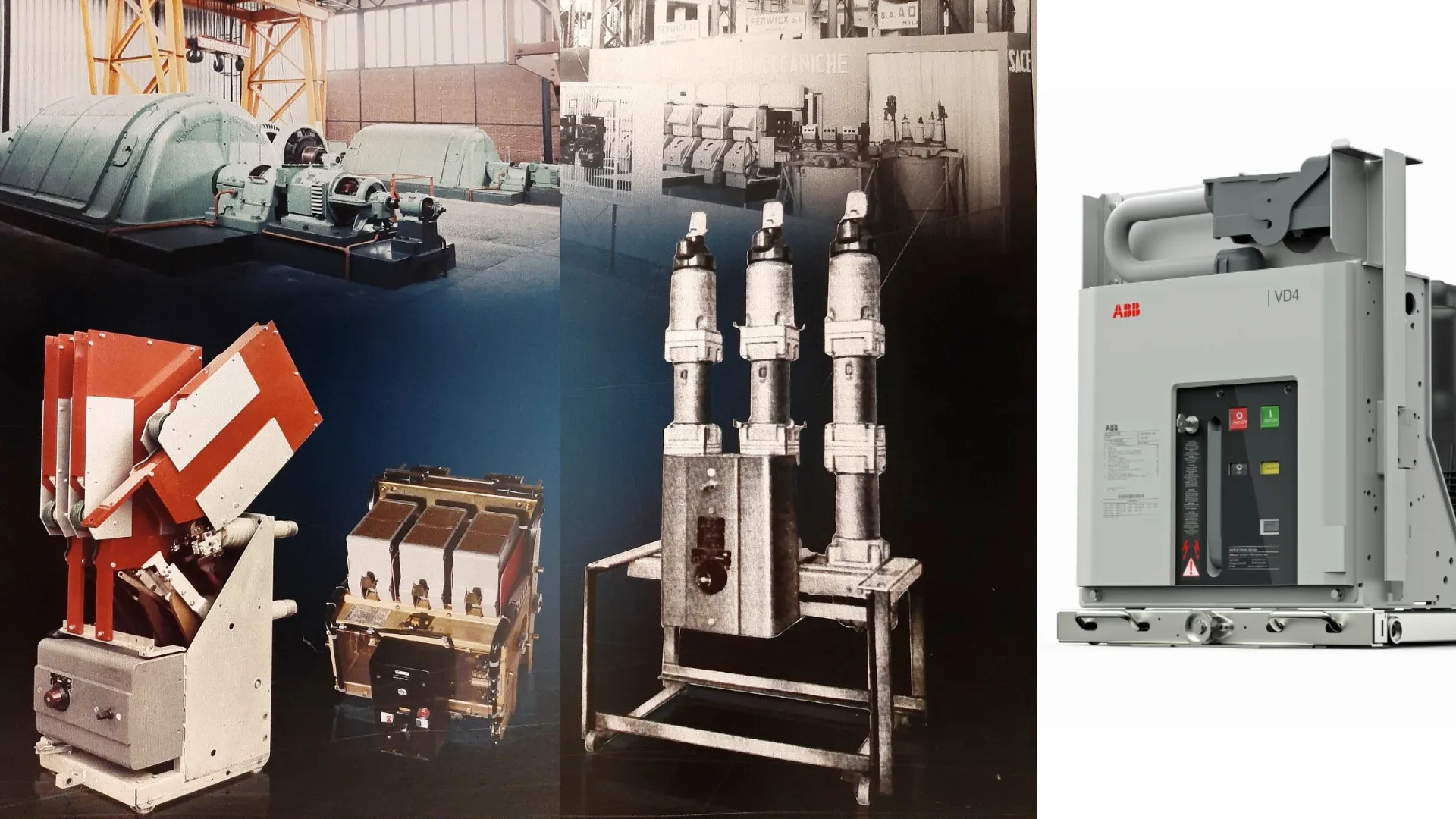

Birth of the circuit breaker

An early form of circuit breaker was described by Thomas Edison in an 1879 patent application, although his commercial power distribution system used fuses. Its purpose was to protect lighting circuit wiring from accidental short circuits and overloads.

In 1924, a miniature circuit breaker — similar to the ones now in use — was patented by a Swiss group of electrical engineering companies, Brown, Boveri and Cie (BBC), which in the intervening years became ABB.

However, it was German engineer Hugo Stotz — who sold his company to BBC in 1918 — and his chief engineer, Heinrich Schachtner, that were generally recognised as the inventors. Stotz and Schachtner’s version made the rapidly increasing electrification of private homes safer and more efficient and was the forerunner of the modern thermal-magnetic breaker commonly used in load centres to this day.

Incidentally, it’s Schachtner’s name that appears on the U.S. patent — No. 1,629,640 — for the miniature circuit breaker, issued May 24, 1927.

“My invention relates to automatic electric circuit breakers of the kind in which two contact pieces normally pressed together by springs are separated by the interposition of an insulating slide,” Schachtner wrote, according to the U.S. Patent Office document.

“When the overload in the apparatus ceases, switching-on can be affected by the mere pressure of the finger without the necessity of unscrewing the apparatus from its socket.”

Prior to circuit breakers, fuse technology was considered cutting-edge — where a metal wire melts when too much current flows through it — when it came to shielding buildings from electrical fires. The problem was the fuse had to be replaced every time there was a fault. Here’s where Stotz and Schachtner produced a revolution by combining thermal and magnetic trips into a single, reusable unit capable of switching off high currents without requiring devices to be replaced repeatedly.

The first serial production of the miniature circuit breaker began in 1928 at the Stotz facility in southern Germany and was met with immediate success, as its device could easily be screwed into the existing fuse base and no changes to the electrical installation were required.

Today, nearly every household is equipped with miniature circuit breakers to stop the flow of electricity, protecting people and equipment from electrical fire.

Pushing the technology further

Being an inventor, Stotz and his team continued to push circuit technology further. In 1928 they developed a special circuit breaker for coping with loads of higher starting currents, including motor applications. This opened the door for industrial applications that nowadays can withstand the harshest of environments, such as dust, humidity and condensation.

Over the years ABB has produced more than a billion circuit breakers and continues to pioneer its evolution through commercial and industrial applications and digital technology. There are versions for an extensive range of requirements, including heavy industries like Oil and Gas plus Marine, as well as large switchgear designed to protect high voltage circuits feeding an entire city.

In fact, the MV VD4 circuit breaker has been the market benchmark for more than 35 years and today, with over 2 million units installed in 100+ countries, helps to bring secure power and energy to homes, businesses, and the infrastructure that keeps the world running.

It’s the model of choice for most modern electricity distribution applications, but since the mid-1980s this little, often overlooked gem, has been leading the way in power distribution for control and protection of cables, overhead lines, transformer and distribution substations, plus motors.

Digitalisation

However, with demand for resilient power 24/7 accelerating at breakneck speed, even the small but perfectly formed circuit breaker has some limits in today’s world. Unfortunately, such is the demand for power, outages and supply shutdowns are still a concern for operators of medium and low voltage switchgear. Such scenarios are not only financially costly, but potentially damaging to corporate reputation too. And for many of these unwanted incidents, the origins are often unknown to the users and operators.

This is where circuit breaker technology has taken another leap into the 21st century through digitalisation, helping end users and system integrators unlock the value of their assets through intelligent insight and data. Original equipment manufacturers and panel builders can now take advantage of smarter integrated and digitally enhanced circuit breakers — complete with Industry 4.0 level sensing technology — without having to completely change installations, make substantial investments or transform operations.

In today’s increasingly challenging times though, it must be about plug and play solutions that make switching to digital operations seamless, simple and cost effective — without having to completely change installations, make substantial investments or transform operations.

One of the first new generation circuit breakers is the VD4 evo, launched September 2022. Its design incorporates sensor enhancements for all thermal, mechanical and electrical parameters along with an advanced Central Monitoring Unit for 24/7, real-time analytics.

With key information delivered via a simple, intuitive dashboard, this approach enables improved visibility of equipment data, status and condition from anywhere in the world — and is completed with diagnostics reports and alarm notifications.

Alongside this, through technological enhancements it becomes easier to predict wear and tear and increase overall lifespan and output, helping to save thousands of dollars per solution when compared to traditional MV switchgear.

The result is a series of significant operational and financial benefits for end users, such as Utilities and Industries. Thanks to the ability to detect issue signals ahead of time, which reduces the risk of power outages by 30%, it is possible to achieve savings in the range of $10,000, depending on the application. It also increases operation and maintenance efficiency by as much as 60%, minimising Opex expenses.

Sustainability

While safety has been the critical driver behind circuit breaker technology since its invention, today, businesses of all sizes are also challenged with adopting sustainable operations. Taking the VD4 evo as an example, its ultra-compact design and energy efficient operation is fully Environmental Product Declaration (EPD) certified. It is 15% smaller and around 30% lighter compared to traditional MV breakers with consequent saving of more than $3,500 per switchgear on footprint square metre cost by itself.

As an essential component of digital switchgear, it also plays its part in helping to save up to 150 tons of CO2 emissions over a 30-year lifetime of a 14-panel unit — the equivalent to a million km in long haul economy flights.

Equally, the ability to make better decisions in all aspects of installation and repair work ensures advanced safety and protection for personnel and maintenance staff.

So, the humble but constantly evolving circuit breaker is now unlocking a more resilient, efficient, safer and environmentally sustainable power distribution network — by facilitating the transition to a brighter digital future.

In the modern smart grid concept, the role of the MV circuit breaker has evolved from a simple protection device to an active apparatus, able to interact directly with the main installation-specific electrical quantities and coordinate operations.

Advancements in sensor technologies have paved the way for making the power grid more reliable, robust, and intelligent, while integration of the new generation of IoT sensor and control electronics is tangibly extending quality and operational performance of the apparatus, as well as opening up new business models.