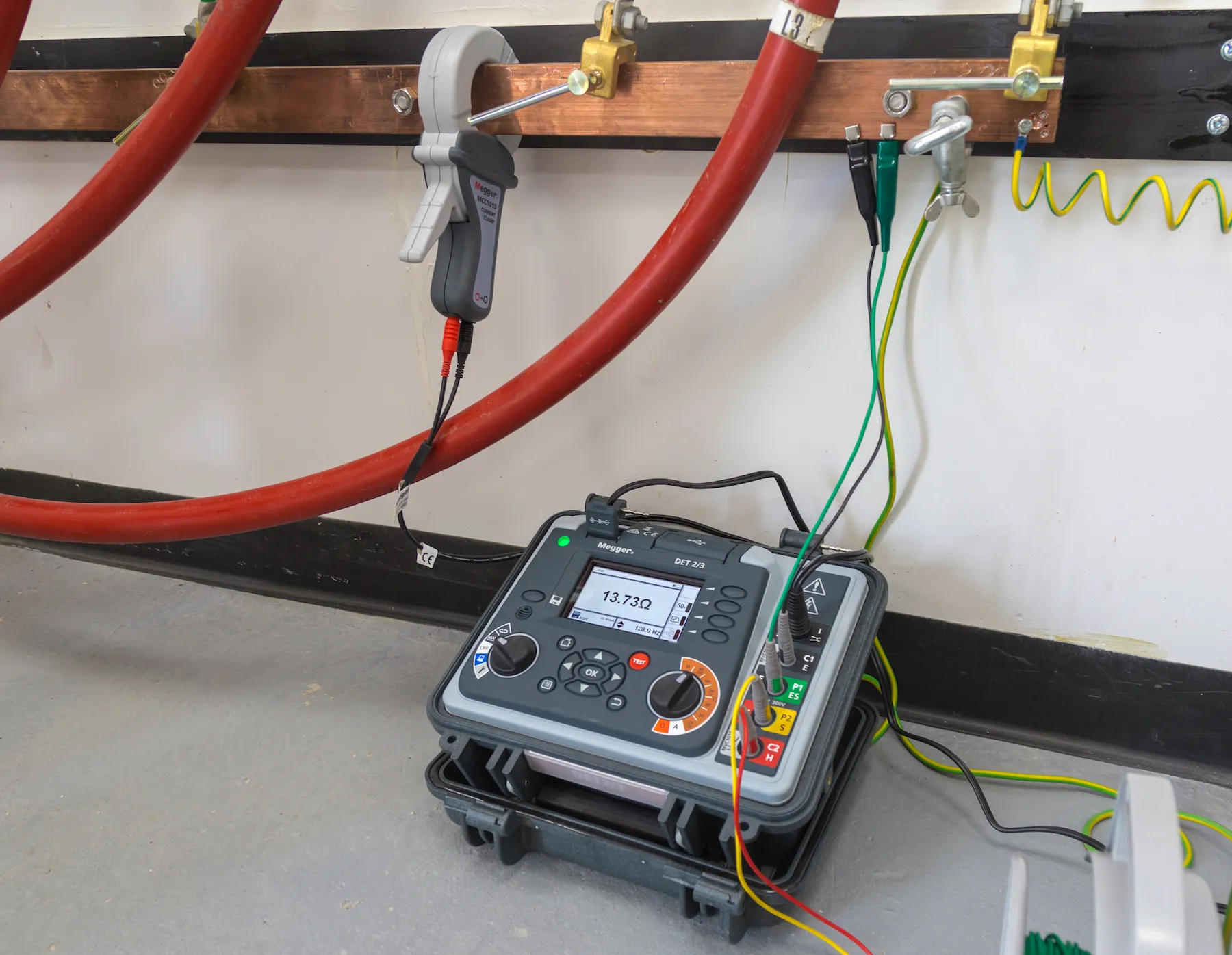

Effective earthing is essential for the safe operation of every electrical system and, according to Ahmed El-Rasheed of Megger, the only way to ensure that earthing installations are effective and that they remain so, is to test them rigorously and regularly.

The vast majority of power distribution systems are designed so that, if an insulation failure or similar fault occurs, the resulting fault current is diverted to earth. This prevents exposed conductive parts from rising to a dangerous potential, while allowing the fault current to flow for long enough and at a high enough level for protective devices to operate and isolate the fault.

It is clear from this description that a reliable, effective earth connection is essential for safe operation of the systems, and that if the earthing system fails or becomes inefficient, at best safety will be compromised and at worst there may well be a significant risk to life and property.

The essential function of every earthing system is to provide a dependable, low resistance connection with the bulk of the earth using one or more earth electrodes, which typically take the form of rods or mats. All earthing systems are designed to achieve this, bearing in mind the requirements of the application, such as the level of prospective earth fault current they may be required to handle. Nevertheless, the efficiency of earth systems is affected by so many hard-to-control variables, such as soil type and moisture content, that it is always essential for the performance of new systems to be verified by rigorous testing during commissioning.

And the requirement for testing doesn’t end with the commissioning tests, as many factors can degrade the performance of earthing systems over time. For example, the moisture content of the soil may change. A good design should have taken into account seasonal variations, but other developments, like a change in level of the local water table, are harder to make allowances for.

Electrodes and the connections to them may also be affected by corrosion, and it’s by no means unknown for earthing systems to sustain physical damage, either accidentally, as might occur during nearby building operations, or deliberately, in the form of theft and vandalism.

All of this indicates that there can be no certainty that an earthing system, even though its initial performance was entirely satisfactory, will maintain satisfactory performance over time. Once again, the only way to be sure is to test it and, given the vital safety role of earthing systems, regular routine testing must be seen as essential rather than optional.

It is strongly recommended that testing take the form of a comprehensive structured earthing survey comprising seven key steps. The first of these is a close visual inspection of the earthing installation. This should look for any signs of damage, for earthing conductors that have been broken, cut or have otherwise become disconnected, and for signs of corrosion, not only to the electrodes themselves but also at the connections between the electrodes and the earth conductors.

All faults will need to be remedied before proceeding with the subsequent testing steps, but it should always be kept in mind that an earthing conductor that has become disconnected may be live, and it is essential to check for this before touching or handling it.

The second step is to measure leakage currents in the earth conductors. Ideally, there should be no current at all flowing in these conductors, but filters and similar devices used in modern electronic equipment often produce a small leakage current even when operating correctly.

Of more concern, however, is electrical equipment which develops a fault that allows it to continue operating apparently without problems, but nevertheless results in current flowing to earth. Such equipment may continue to be in use for long periods, with the operator being unaware of the problem, but it is clearly essential to detect such leakage current before carrying out further tests on the earthing system, and the most convenient way to do this is usually to use a clamp meter capable of measuring currents in the milliamp range. If significant current is detected in the earthing conductor, the source must be traced and the problem rectified before proceeding further with testing.

A final preparatory test is to electrically test the continuity of the earth conductors to confirm the integrity assessment made during the visual inspection of the system. The purpose of this test is to detect and locate high resistance joints, which are a typical result of corrosion in exposed conductor systems.

It is important to bear in mind that, in this context, ‘high resistance’ means anything from a hundred micro-ohms or so upward. Resistance values of this order cannot be measured with an ordinary multimeter, so it is essential to use a low-resistance ohmmeter (also known as a micro-ohmmeter) for this test.

After the visual inspection of the earthing system has been completed, the absence of leakage confirmed and the continuity of the conductors verified, it is necessary – for a full earthing survey – to disconnect the earth electrodes. Under no circumstances must earth connections be broken until the safety implications have been fully evaluated and the appropriate steps taken to minimise risks.

This will typically involve de-energising and locking out the equipment, which is to be disconnected from earth, but it is also essential to consider the potential hazards of induced voltages, which may be present in unearthed equipment even when it is not energised.

As an aside, it is worth noting that there are techniques for measuring earth resistance without disconnecting the earth electrodes. These include, for example, ART (attached rod technique) and stakeless testing with clamp-on testers. These techniques are useful, but all have limitations, and it is universally accepted that testing by the fall-of-potential method, which necessarily involves disconnecting the electrode or electrodes under test, delivers the most accurate and reliable results. For definitive earth resistance surveys, therefore, the fall-of-potential test method should be used.

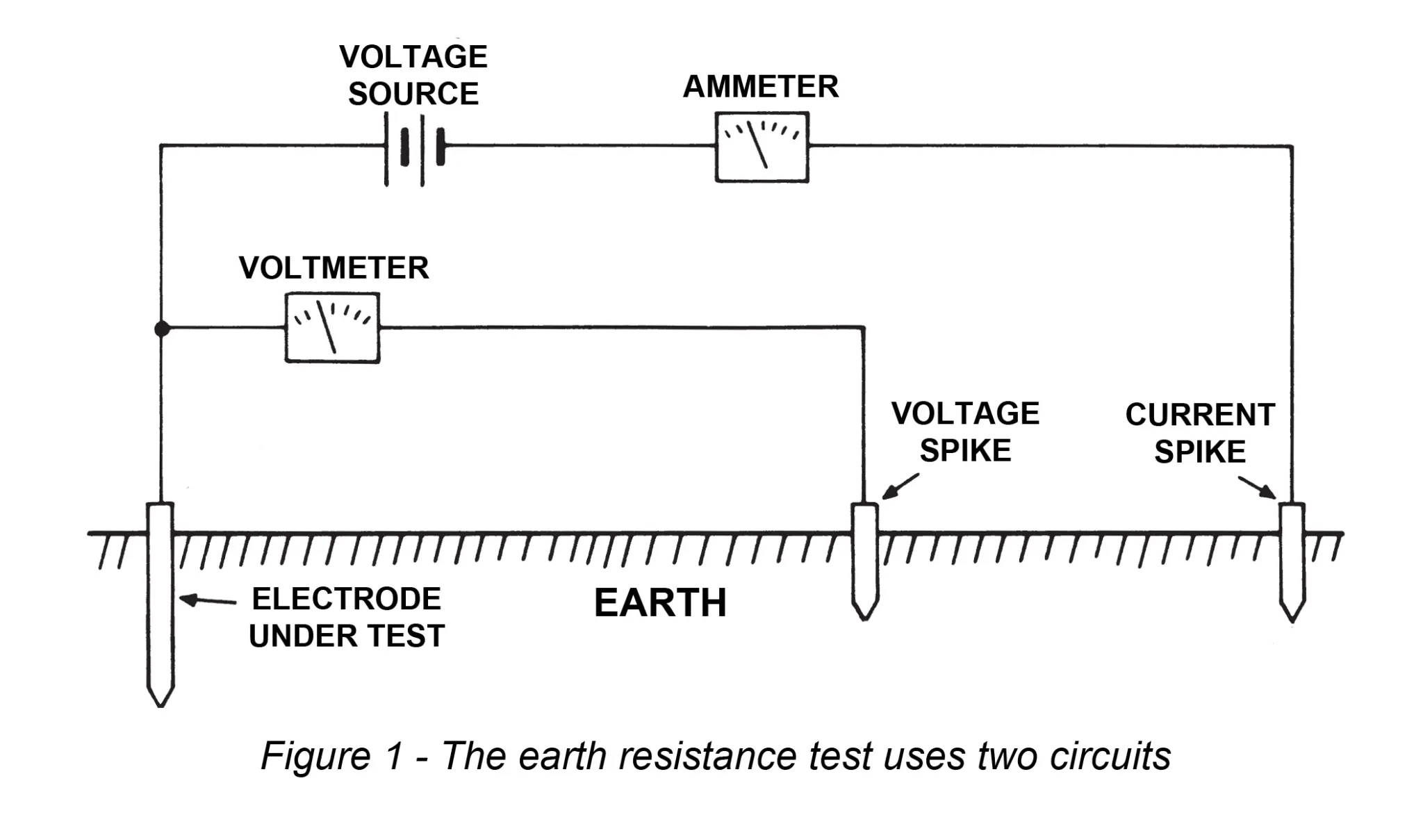

This test is performed with an earth resistance test set that essentially comprises two circuits, as shown in Figure 1. The first circuit includes a voltage source and an ammeter, and it is brought out to the instrument’s current terminals. The second circuit includes only a voltmeter, and is brought out to the instrument’s voltage terminals. One of the current terminals and one of the voltage terminals are connected to the electrode under test. The other current terminal is connected to a temporary earth spike that is inserted into the earth a considerable distance away from the electrode (the current spike), while the other voltage terminal is connected to another temporary earth spike (the voltage spike).

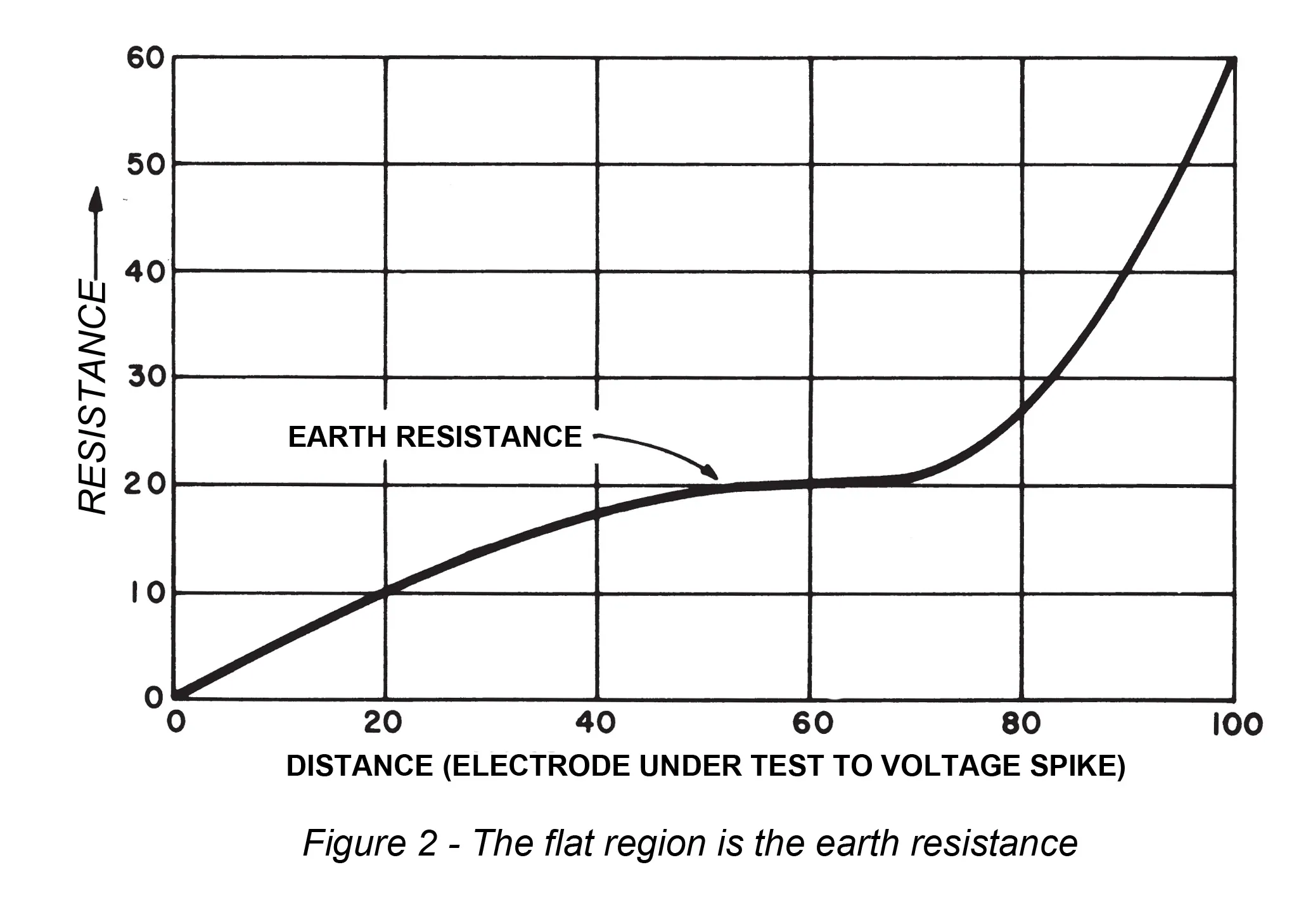

The voltage spike is inserted into the soil at various distances along the straight line between the electrode under test and the current spike and, at each distance, the voltage reading is noted. Since the current is also known, it is then possible to use Ohm’s law to calculate a resistance value for each location of the voltage spike. If the resistances are plotted against distance, the curve should show an almost flat region (see Figure 2). The resistance value in this region is the resistance of the earth electrode.

The procedure is necessarily more complex for systems with multiple electrodes or with earthing grids but helpful information covering these situations, and explaining earth testing in much more detail can be found in the publication, ‘Getting down to Earth’, which is available as a free download from the Megger website.

As part of a comprehensive earthing survey, it is also important to carry out tests to determine touch and step potentials, touch potential being the potential difference a person might experience if they were standing on an earth surface and touched an earthed conductive object while a fault was producing a current flow to earth. Step potential, is the potential difference a person would experience between their feet over ground in which a fault current existed.

Touch potential is determined by first measuring the resistance to earth of the object in question, using techniques similar to those used to measure the resistance of an earth electrode. When this resistance is known, along with the maximum prospective fault current, Ohm’s law can be used to calculate the worst-case touch potential with a reasonable margin of accuracy. Step potential is evaluated in a similar way, but when the earth resistance measurement is performed, the voltage spikes are hammered into the ground about one metre apart, as this is the approximate length of the average person’s step.

The procedures outlined so far provide invaluable data about the condition and performance of an earthing system, but it is often also useful to know about the properties of the soil in which the earthing system is located. Some of this information is obtained by inspecting and examining the soil to determine its type, but it is also important to carry out earth resistivity measurements. Note that these measurements relate only to the intrinsic resistivity of the soil, whereas the earth resistance measurements discussed earlier relate to the resistance of a specific earth electrode (or electrodes).

Earth resistivity testing can usually be carried out using the same instrument used for earth resistance testing, with one proviso: the instrument must be a four-terminal type with the voltage and current connections brought out to separate terminals. Three terminal instruments are not suitable for earth resistivity testing.

Earth resistivity is usually measured using the Wenner method, which involves the use of four temporary earth spikes. The spikes do not need to be moved as part of the testing procedure however – their location and spacing is determined by the depth at which it is required to determine the earth resistivity.

Earthing is a fundamental requirement for the safety of electrical installations, but all too often the effectiveness of earthing systems receives scant attention, especially after initial performance has been verified. This is dangerous and unnecessary. As we have seen, the performance of earth systems can be reliably evaluated by an adopted structured, step-by-step approach and, while it can be argued that the procedures involved are time consuming and, to a certain extent disruptive, surely this is a small price to pay for protecting human life?